Introducing the TankCare™ FQC Scheme

The unique TankCare™ FQC (Fuel Quality & Certification) Scheme is an independent fuel certification scheme for fuel distributors, authorised by the FPS (Federation of Petroleum Suppliers). It is designed to protect distributors against one of the biggest risks they face – the alleged delivery of dirty fuel.

The FQC Scheme regularly measures stocks for contaminants to accurately predict if fuel is likely to deteriorate in quality, before providing accreditation and assurance of quality levels.

This provides peace of mind for distributors, achieves a quality seal of approval for storage tank hygiene and fuel quality at distribution depots and raises the quality of fuel standards across the industry.

How does it work?

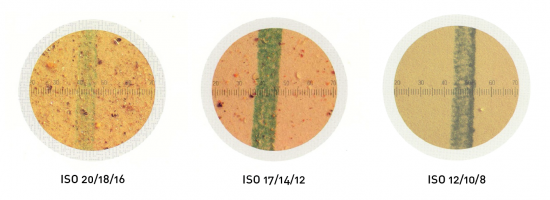

The FQC Scheme works by first testing oil and diesel storage tanks at six weeks, followed by a second round of testing at six months, looking for particulate, water content and biological contaminants. These testing procedures are the fastest, most accurate and least expensive method for monitoring and controlling microbial activity. The tests detect as little as one living cell per millilitre, allowing TankCare™ to track and predict potential contamination risk in the fuel and certify it as safe when optimum bio-levels are reached. Fuel is certified at the six-month mark if it passes the strict tests, and these tests are repeated every six months. This ensures quality is maintained and allows time for measures to be taken if fuel quality starts to drop.

Why is this important?

Dirty fuel is more likely to be caused by a customer’s dirty storage tank. The good news is that a distributor certificated under the new Scheme would be able to prove to a court of law that their fuel was clean when it left their depot whereas it is unlikely that a customer making a claim of dirty fuel being delivered, could prove their storage tank was clean and fit for purpose at the time of delivery. It makes good business sense for distribution companies to be able to prove, through participation in the FQC Scheme, that they are a clean fuel supplier as it is a marketing advantage over any competitors not certified.

Fuel quality is paramount. It has been proven by a number of extensive trials that clean fuel reduces filter blocking risks, tailpipe emissions and fuel usage, so it is high on the Government’s legislative agenda. There is a long-term need for testing and certification to secure the standards the industry must have.

About 50% of all fuel now sold in the UK is imported. Some of these fuels have additives put into them to bring them within the required standards for sale in the UK. The problem is that there is no requirement for the companies producing these fuels abroad to declare what additives have been used, and most are not tested by an independent Test House to prove their long-term effect on engines or emissions. Mixing different additives can also result in reactions which can lead to filter blocking or even cause engine breakdowns.

The Government’s focus on the environmental impact of fossil fuel will lead to further changes in fuel composition. It is well known that FAME (Fatty Acid Methyl Ester) is hygroscopic, and therefore adsorbs water into suspension in fuel, enhancing the risk of bacterial growth. At present Gas Oil and Derv have up to 7% FAME but the Government is looking to increase this to 10% or above which will inevitably increase the risks of bacterial growth.