Protecting Against Fuel Contamination: The Benefits of Fuel Polishing and Testing

Fuel contamination is one of the leading causes of equipment failure, reduced efficiency, and operational downtime in industries that rely on fuel-powered machinery and backup generators. To ensure that fuel remains clean and reliable, businesses need to adopt fuel polishing and fuel testing as integral parts of their fuel management strategy.

Contaminated fuel not only risks damaging engines and equipment but also shortens the lifespan of storage systems.

What is Fuel Polishing?

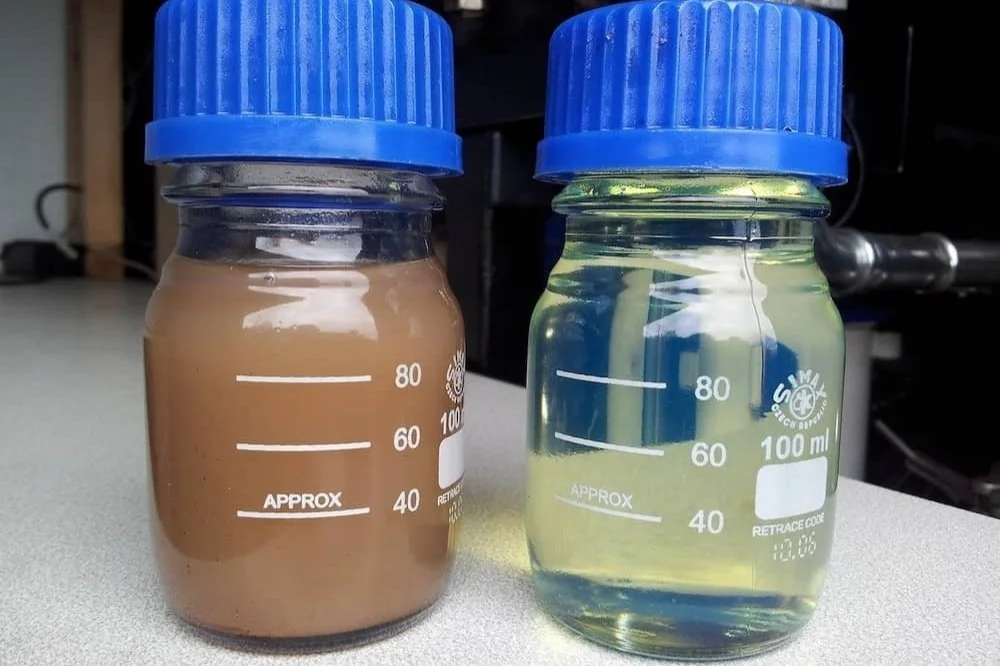

Fuel polishing is a cleaning process that removes contaminants from stored fuel, such as water, microbial growth, sludge, and sediment. This process involves circulating fuel through a specialised filtration system to restore it to a usable condition. Fuel polishing is especially important for diesel fuel, which is susceptible to microbial contamination and degradation over time.

What is Fuel Testing?

Fuel testing involves regularly analysing fuel quality to identify potential contaminants or degradation before they cause problems. Testing can detect water contamination, microbial growth, and chemical changes that can reduce fuel efficiency and cause engine damage. By routinely testing fuel, businesses can ensure it meets the required standards for performance and safety.

OTS Group rectangular tanks are certified to OFCERT OFS T200, meaning that unlike the BS799 Part 5 2010 standard, which only covers the primary tank, the OFTEC OFS T200 certification includes the bund, providing an enhanced specification. Cylindrical tanks are certified to EN-12285-2 standard, and Class A and structural slab tanks are certified to local and international standards.

Why Prioritise Fuel Polishing and Testing?

1. Prevent Equipment Failure

Contaminated fuel can wreak havoc on engines, backup generators, and other fuel-powered machinery. Water and sediment can clog fuel injectors, while microbial growth can lead to fuel degradation, resulting in poor combustion and engine wear. By removing these contaminants through polishing, organisations can protect their equipment from breakdowns and extend its operational life.

Routine fuel testing also helps detect contamination early, allowing for corrective action before it impacts performance. Regular testing ensures fuel remains within the necessary parameters for reliable and efficient operation.

2. Extend Fuel Storage Longevity

Fuel stored for extended periods is prone to contamination, especially in environments with fluctuating temperatures or high humidity. Over time, condensation can lead to water accumulation in storage tanks, which encourages microbial growth and sediment build-up. Regular testing of stored fuel provides a clear picture of its condition and polishing helps maintain its quality, ensuring it can be stored safely for longer periods without the risk of contamination. This helps businesses avoid the need to dispose of contaminated fuel, reducing both waste and costs while ensuring the longevity of fuel storage systems.

3. Improve Operational Efficiency

Clean, high-quality fuel improves the overall efficiency of operations. Engines run smoother, fuel consumption is optimised, and the risk of unplanned downtime is greatly reduced. Fuel polishing helps keep fuel in prime condition, reducing the need for frequent maintenance and repairs caused by poor fuel quality.

By incorporating fuel testing, businesses can predict when tank maintenance is needed, preventing sudden equipment failures and ensuring that fuel systems remain reliable throughout their operation.

4. Compliance and Environmental Responsibility

In industries where environmental regulations are stringent, maintaining fuel quality through polishing and testing is essential. Poor fuel quality can lead to higher emissions, environmental spills, and non-compliance with industry standards. Implementing fuel polishing and testing ensures that fuel systems operate within regulatory guidelines, protecting businesses from potential fines or reputational damage.

How OTS Group Can Help

With our dedicated environmental facility, OTS Group offers more ways than ever to support your fuel storage needs. In addition to on-site fuel testing, we provide fuel uplift services, allowing us to transport your fuel to our facility for professional polishing using advanced filtration technology.

Our fully equipped ADR-rated vac tanker enables safe and efficient vacuum extraction, while our high-performance polishing rigs restore fuel quality to optimal levels. Once processed, we can return your polished fuel or, if preferred, purchase your redundant fuel through our We Buy Any Fuel scheme, ensuring a cost-effective and responsible solution for fuel management.

Our comprehensive maintenance services help organisations extend the lifespan of their fuel storage systems, prevent contamination-related issues, and maintain compliance with the highest industry standards.

Don’t leave your fuel quality to chance. Contact OTS Group today to discuss how we can help keep your fuel clean and your operations running smoothly.